‘Don’t Be a Part of Pollution. Be A Part of the Solution’

– Rudra Environmental Solution Ltd.

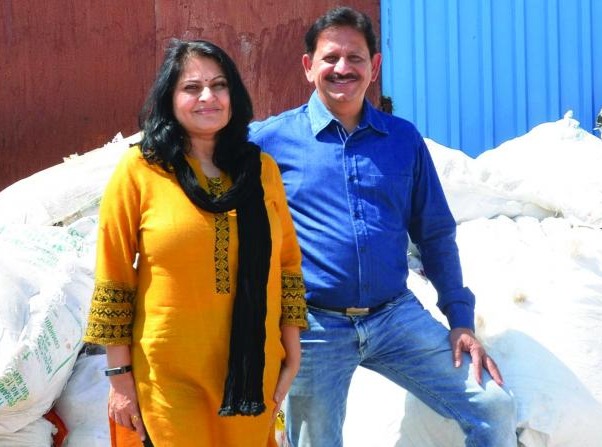

The plastic warriors, Mr. Shirish Phadtare and Dr. Medha Tadpatrikar of Rudra Environmental Solutions spoke about innovative and sustainable lifestyle in an interview with Sustain and Save which was conducted by change maker Mr. Achyut Vanarse, pursuing architecture from the SMEFs BRICK School of Architecture and a dynamic leader at Sustain & Save.

“We at Rudra Environmental Solutions very strongly believe in Social transformation through Innovation. We believe invention can solve many of the biggest social, environmental and economic challenges of our time.” - Rudra Environmental Solutions.

Being a photographer by passion, Mr. Phadtare was on a sanctuary visit when they weren’t allowed entry to a specific place, reason being the death of a deer. On digging further into the issue, it was known that the animal’s death was caused due to plastic consumption. This very incident triggered him and led to the formation of the entity. Being inspired to do something about the plastic waste generation, the founders thought of recycling and re-using plastic. The company focuses and researches on ways of converting waste plastic into fuel technology through TCD i.e. Thermo Catalytic Depoly merisation Process.

But it wasn’t a cake walk for the venture. When tried to communicate his idea to create poly-fuel from plastic, Mr. Phadtare faced a lot of rejections and was suggested to drop the plan of working on & creating a business in environmental solutions by Chemical, Mechanical and Instrumentation Engineers and even specialists from related fields. But with hard work and persistence, the duo got to their ‘eureka’ moment.

How do they work?Firstly, plastic is collected by Keshav Sita Foundation from all over Pune. It’s then taken to the plant near Jejuri and then put into the reactor along with a catalyst (TCD Process). For approximately 100 kg of plastic, 50-70 litres of poly-fuel is produced, along with 20-30 kg of gas being produced with 5-7 kg of residue. The gases are used to re-heat the reactor and the residue is used in roads by combining it with bitumen and aggregate. This assists in zero-waste, recycling and re-use of used plastic.

Over the years, Rudra Environmental Solutions has earned the trust and investor from a Singapore based firm. Moreover, they have successfully established and handed over the ownership of 3 plants and kept 3 under their ownership. They have achieved a milestone in their journey of reducing plastic going in the landfills by converting a few 100 tonnes of plastic till date.

Knowing and learning about such green missions, it sets us thinking whether is it really so difficult to use, and not abuse products and waste? Do we really want to see our surroundings covered with 12 billion metric tons of plastic? Instead of being a problem, let’s be the change and help and work towards a cleaner, greener and sustainable ecosystem.

By : Riya Nathe