Learn how to measure the environmental impact of products and buildings through Life Cycle Assessment (LCA) and Environmental Product Declarations (EPDs).

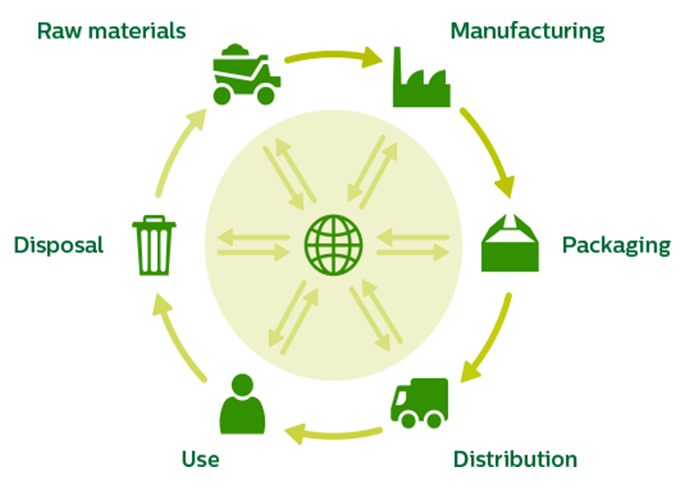

Reducing carbon emissions starts with understanding them. Life Cycle Assessment (LCA) provides a scientific framework to measure the environmental impact of a product, service, or building across its entire lifespan - from raw material extraction, manufacturing, use, and end-of-life disposal. When these assessments are standardized and verified by a third-party, they can be published into Environmental Product Declarations (EPDs) - a transparent document that communicates a product’s carbon footprint and other environmental indicators. By revealing both visible and hidden emissions, LCA empowers designers, developers, and policymakers to make informed sustainability decisions.

Cradle-to-Grave Thinking

LCA and EPDs analyze every stage of a product’s life:

- Cradle - Raw Material Extraction: It quantifies the environmental impact embedded in the product/ building’s raw materials, which are usually procured through a vendor or supplier. Ideally, the vendor or supplier should disclose the product’s impact, but in most cases, these figures are not available. In such cases, the impact is accounted for through a database like Ecoinvent.

- Gate - Manufacturing, Transport, and Installation: These are impacts arising from the manufacturing process, transport of raw material, and installation activities—including fuel consumption, utilities like electricity, diesel, and any wastage produced during installation.

- Operational Impact: This phase measures the impact of maintenance, use, energy consumption (if applicable), or repair of the product/ building when it is in use.

- Grave - End-of-Life Disposal or Recycling: Finally, the impact of the End-of-Life from demolition, waste processing, and potential recycling or reuse of materials is accounted for.

This holistic view captures both direct and indirect emissions of the product or building, ensuring nothing is overlooked in the assessment.

The focus on Built Environment - Why It Matters

Buildings contribute nearly 40% of global carbon emissions, yet traditional assessments often focus only on operational energy. Embodied carbon, from materials and construction processes, can account for up to 40% to 50% of total lifetime emissions in buildings. Ignoring embodied carbon risks underestimates environmental impact and misses opportunities for material efficiency and sustainable sourcing.

LCA provides full transparency, allowing stakeholders to pinpoint emissions hotspots right down to the specific material and its contribution to making decisions for replacing conventional products with a low carbon product - one that truly reduces a building’s footprint. A low-carbon product can be something with recycled content or locally produced or made using renewable resources. This is why EPDs are important - they bring the level of transparency required to make such decisions for each raw material used.

Tools & Standards

Several standards and tools support accurate LCA and EPDs:

- ISO 14040 & ISO 14044: International standards for Life Cycle Assessment methodology.

- EN 15978: European standard for assessing the environmental performance of buildings.

- Software tools:

- One Click LCA: widely used in LEED, BREEAM, and IGBC projects for embodied and operational carbon calculations.

- SimaPro: An advanced tool for detailed LCA modeling.

- Ecoinvent: A widely used database with the embodied impact of raw materials found globally.

- Integration with certifications: LCA & EPDs are a crucial part of the material credit of green building rating systems, providing credits for low-carbon design choices.

- EPD: An LCA study is also a prerequisite for getting an EPD published.

By using these tools, architects, engineers, and OEMs can quantify the impact of every material, system, and process, ensuring that decisions are data-driven rather than assumption-based.

The Way Forward

Measuring environmental impact is the first step toward managing it effectively. With LCA:

- Material choices can be optimized for low-carbon alternatives, such as recycled steel, low-carbon concrete, or sustainably sourced timber.

- Energy systems can be designed for efficiency, integrating renewables and smart controls.

- Circular economic strategies - reuse, recycling, and modular products/ construction methods can reduce end-of-life emissions.

- Policy and industry transformation through widespread LCA adoption pressure suppliers and manufacturers to decarbonize products.

In short, LCA and EPDs turn measurement into action, helping the construction sector move toward a truly sustainable future.

Graph showing embodied vs operational carbon emissions.

Authors:

Siddharth Bhagwat, Head of LCA & ESG at Sustain and Save

Ar. Simran Deshpande, Green Building Associate at Sustain and Save